Laboratory

The Laboratory has approved by Institute of standard and industrial research of Iran (ISIRI) for rail accessories.

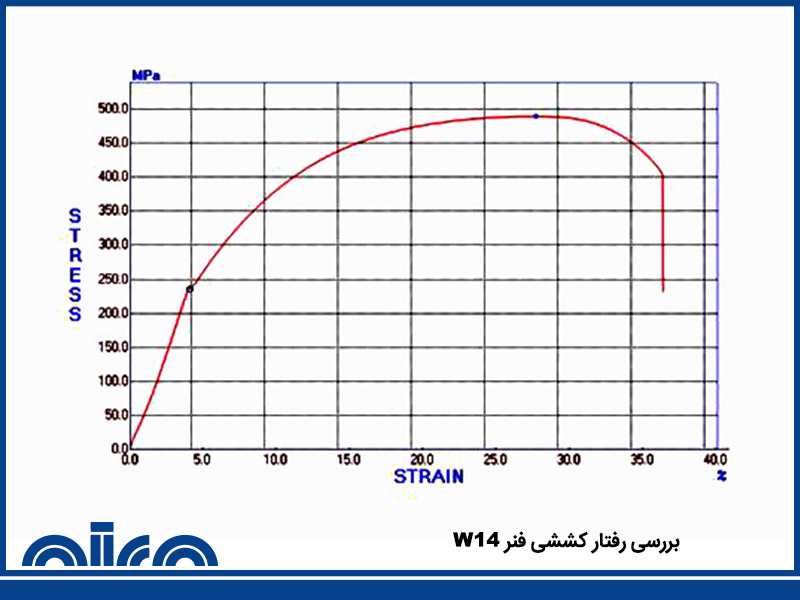

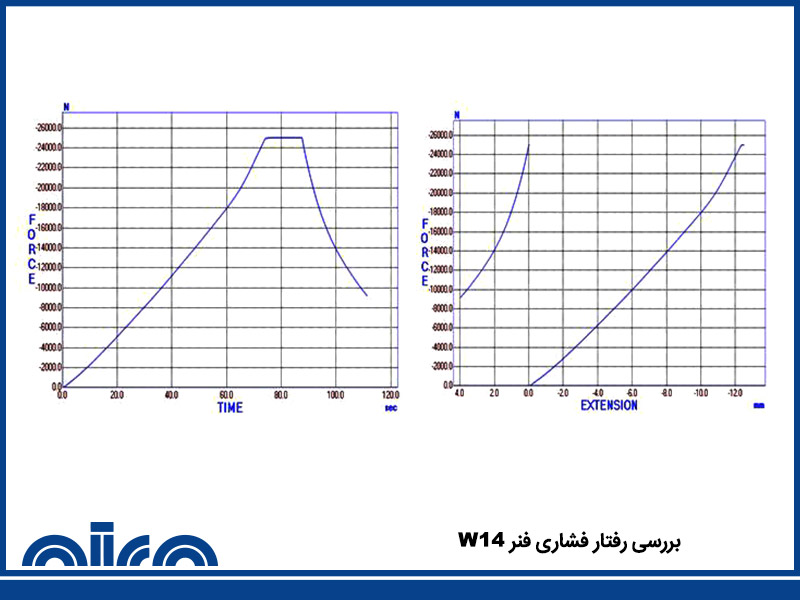

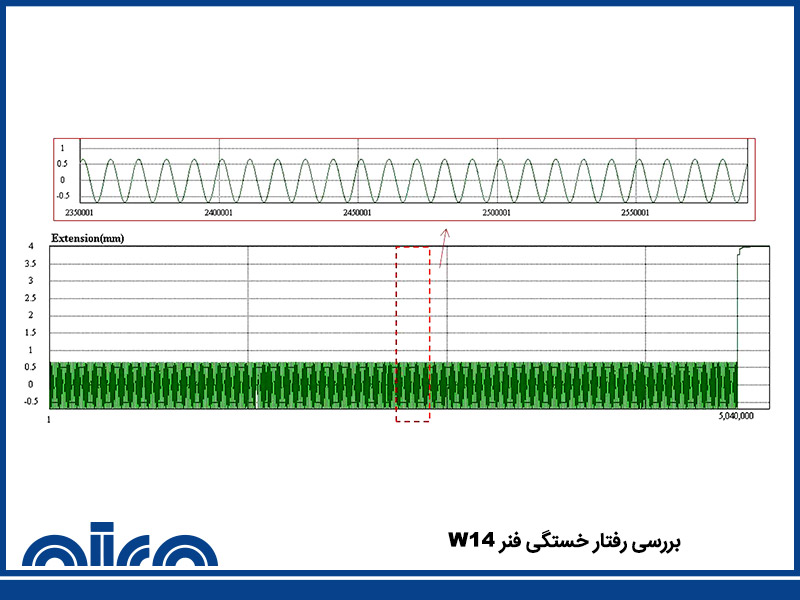

General tests including tensile, compression, hardness, fatigue, metallography and microscopic construction for raw material and finished parts are done according to valid standards. special tests could be performed on customer demand accordingly.